UV LED is greener, cheaper & better

UV LED and RESUCAT 210-29 uv ink series provide excellent advantages for printers, as LED is better for people and the environment, cost effective and produces low odor print as well as a number of other benefits.

You can only achieve these advantages if you also use printing ink optimized for ultraviolet LEDs.

RESUCAT inks from Resino are well known for food safety, adhesion to plastics, boiling and sterilization resistances.

For the last few years, Resino has worked on a LED optimized version of the RESUCAT UV flexo inks and is now ready to launch the low odor UV LED curing ink, RESUCAT 210-29 series.

Why should you choose an UV LED system? Here are our thoughts.

Greener

Environmental advantages with UV LEDs

First of all, UV LED is more environmentally friendly compared to mercury arc lamps. It is very important that the industry focuses on the environmental aspects and moving to a mercury-free economy reduces emissions to air, the impact on land and water, as well as damages towards people’s health.

Choosing UV LEDs also contributes to eliminating emission of ozone. Traditional lamps emit ozone, which smells and is not healthy for humans nor the planet because ozone at ground level is air pollutant. Therefore, eliminating ozone will improve the air and the working environment.

The energy output of UV LED lamps are safer, as the energy output contains no UV B and UV C – only UV A. As contrast, the energy output of standard mercury lamp contains both UV B and UV C.

UV LED Lamp vs. Standard Mercury Lamp

UV LED & standard mercury lamp

The Minamata Convention on Mercury

The UN has established the Minamata Convention on Mercury which is a global treaty aimed to phase out mercury to protect people and the environment from the damaging effects of mercury. Among other things, the Minamata Convention on Mercury phases out and reduces the use of mercury in several products and processes, bans new mercury mines, phases out existing mercury mines and controls measures on the impact on the environment (air, land, and water). You can read more about the Minamata Convention on Mercury through this link.

This means that companies need to find solutions to phase out mercury in products and processes. The traditional UV lamp is also made of mercury, whereas the UV LED lamp is free of mercury.

Reduce energy

We know from our own household that a switch to LED light bulbs save energy. This is also the case when changing from UV mercury lamps to LED UV.

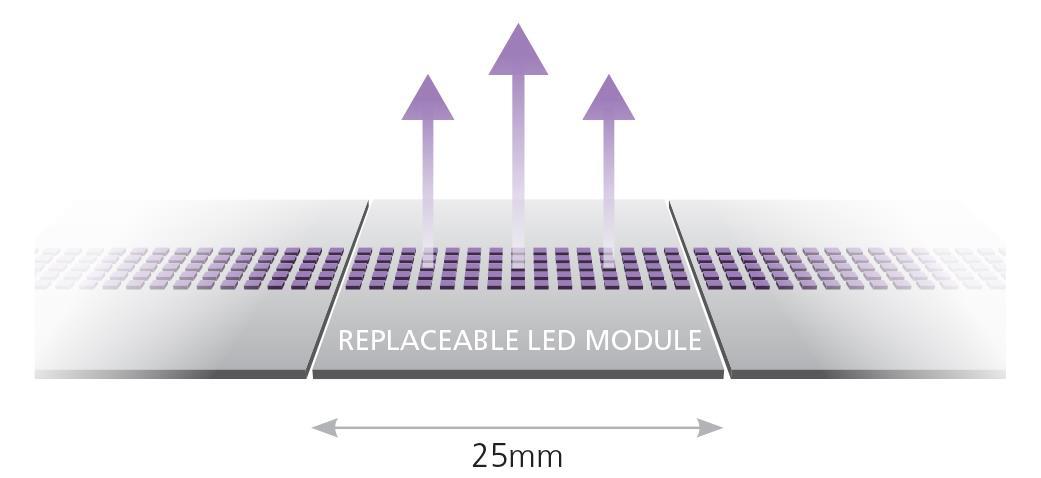

Using a UV LED system, the outside segments of ultraviolet light can be turned off to cure a smaller area. For example, if the arch lamp is 400 mm wide, it will heat and light up at 400 mm when turned on.

Many printers print on meat casings which are 65 or 100 m wide. Thus, only part of the lamp emission is actively exposing the substrate.

This gives you the opportunity to optimize energy consumption with UV LED lamps, as you can turn the UV light off in the areas where UV light exposure is not needed.

Choosing LED lamps will be good for the company’s economy and the environment.

Cheaper

Higher press speed

Using UV LED systems, you will experience a very fast cure response. This is more cost efficient, as you can print at a higher speed, thus increasing the productivity.

Long lamp life span

The lifetime of UV LED lamps is more than 20,000-60,000 hours. Therefore, you can use the UV LED lamp for up to 3 years.

Less maintenance

Mercury arc lamps have shutters and reflectors which require attention and maintenance to assure performance and consistency. UV LED lamps do not have shutters and reflectors, thus this maintenance is avoided, thereby more cost efficient.

LED array diodes. Courtesy of GEW.

Better

Low heat emission from lamp, inducing less shrinkage on substrates

An UV LED system does not generate as much heat.

Therefore, films, shrink sleeves and other delicate materials can be processed without heat damage.

High intensity peak

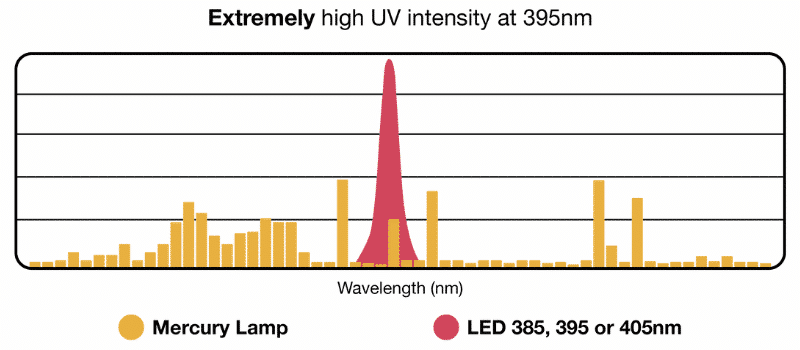

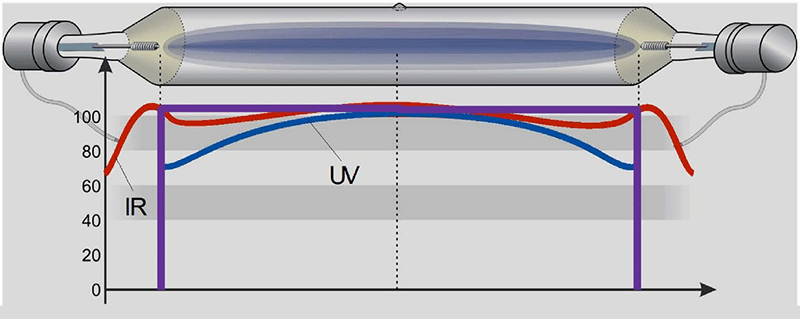

There is a very high energy directed to the specific area, as the UV LED lamp is concentrated at a narrow wavelength. Mercury arc lamps have a poor uniformity, especially in the edges, which you do not experience with UV LED lamps.

UV intensity

Better curing

UV LED is highly effective, as it also allows the ink to dry faster. The UV LED system also provides more predictable and controllable curing which creates stability for the customer. In this way, the customer can also achieve more constant quality.

Relative intensity exposure to the substrate. Courtesy of Phoseon.

Optimized productivity

LED UV lamps are at full intensity immediately when turned on, whereas Mercury lamps need time for warming up and cooling down.

Using UV LED gives increased press productivity because you do not have to wait for lamps to be ready. In case of printing too soon with mercury lamp curing, you may experience poor drying on press, generating waste. This is reduced by using UV LED.

Low odor

As mentioned, UV LEDs do not emit ozone which is unhealthy for people and the environment. Furthermore, ozone also has an unpleasant chemical odor which will be avoided when choosing UV LED systems.

Overall, UV LED and RESUCAT 210-29 series provide excellent advantages for printers, as LED is better for people and the environment, cost effective and produces low odor print of same or higher quality.

Why is a different ink variant needed for UV LED?

Traditional mercury arc lamps spread the output intensity over a wide spectrum of wavelengths, whereas UV output of LED lamp is concentrated around a narrow spectrum.

For this reason, it is necessary to adjust the inks, so the curing activity fit exactly to the lamp output wavelength. Therefore, Resino has adjusted the photoinitiator(s) in the ink to absorb specifically in the same wavelength as the peak irradiance of the LED lamp providing fast drying.

This adjustment is particularly difficult for pigmented systems, where also the pigment must be selected to have the lowest absorption at the specific wavelength.

Therefore, if all the advantages of UV LED system shall be available, there is a need for cooperation between lamp producers, printing companies and ink suppliers.

Do you want UV LED inks?

Our new ink series, RESUCAT 210-29, is a cationic UV curing ink for flexo printing. RESUCAT 210-29 has very high resistance properties, including boiling-, oil-, grease-, heat- and frost resistances. The LED UV ink series is designed with a raw material selection to maintain the food safety and migration characteristics as obtained with other RESUCAT 210 ink series.

The RESUCAT ink range is also suitable for flexible packaging, including shrink sleeves, shrink bags, retort & wet sterilization resistant print and much more.

We are happy to assist in your process around UV LEDs and how it can be implemented by your business.