NEW STERILIZATION RESISTANT RESUCAT® 210-29 UV LED INKS

RESUCAT® 210 UV LED series inks from Resino are known for its high demand features such as boiling & sterilization resistances, excellent adhesion to polyamide, high quality print and a low risk of migration which made the product attractive to customers for printing on sausage casings and food packaging.

We at Resino Inks previously described our opinions about good reasons to replace traditional UV curing print by LED UV curing print. That describes environmental advantages, Minamata convention legislation & lamp difference details. If you wish to read that paper, click here.

RESUCAT® 210-29 UV LED - Setting the standard

RESUCAT® 210 series inks from Resino are known for its high demand features such as boiling & sterilization resistances, excellent adhesion to polyamide, high quality print and a low risk of migration which made the product attractive to customers for printing on sausage casings and food packaging.

Through several years Resino Inks has provided customers with a safe and healthy line of printing ink. The RESUCAT® 210-29 series is built on all the best properties from our well-known RESUCAT® 210 series and has been adjusted with LED curing principles. It is a further development of a known and thoroughly tested technology which has proven great results.

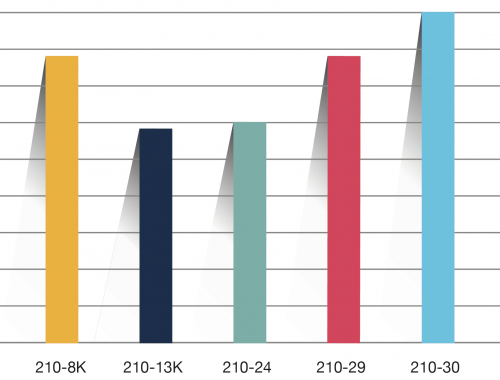

Price levels

Tape/scratch/boiling resistance

Furthermore, the colors of the 210-29 series have extremely low odor, fast curing and energy saving.

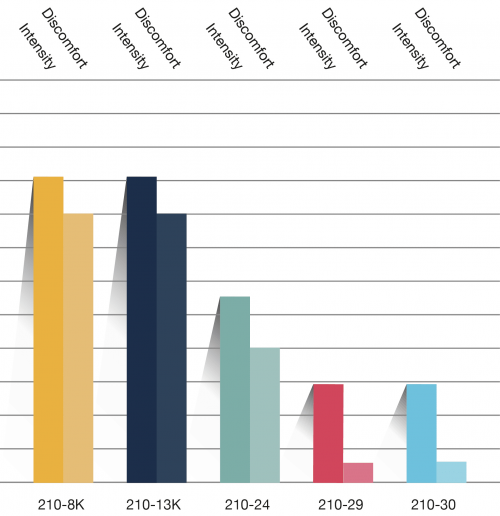

Odor level

We notice some label UV LED printers are discussing “Dual-cure” inks, where the ink can cure using traditional mercury lamps or LED lamps. RESUCAT® 210-29 series also can be cured by traditional mercury lamps and therefore may be referred to as “Dual-cure” inks. The aim is that ultimately all future UV colors from Resino will be UV-led curable.

“Our aim is to help more printers to switch to UV LED – thereby heading towards a more sustainable environment and a healthier work environment”

Kristian Karlsen, R&D Director at Resino.

Benefit for businesses

The LED technology comes with a lot of technical advantages and is more energy-efficient than traditional UV lamps. LED is better for the environment, it is cost effective and produces low odor print of same high quality as traditional print with other RESUCAT® 210 inks.

With the RESUCAT® 210-29 series it is possible to use both 395nm and 405nm lamps. The 395nm can be used on all the print stations (White, colors & varnishes), whereas the 405nm provides increased performance for the white station, because the white pigment absorbs less UV light above 400 nm.

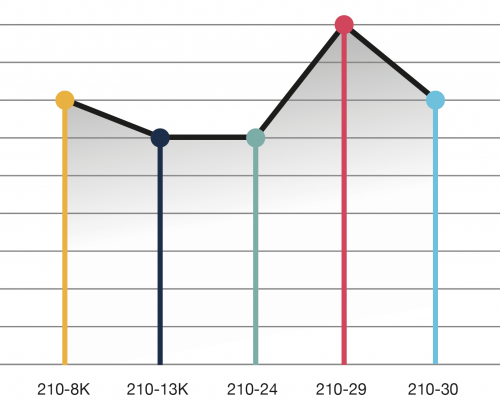

Extremely high UV intensity at 395nm

Intensity

LED is more efficient, because of the higher intensity peak at a narrow wavelength spectrum. This enhances the absorption in the print and increase curing, enabling faster printing speed.

Also, the UV LED system provides more predictable and controllable curing which creates stability for the customer. In this way, the customer can also achieve a more constant quality.

The faster printing speed has been confirmed during trials at several customers.

Cure response

Customers have confirmed the end use performance and fast-curing speed. We are already supplying regularly in the marketplace and have further approvals pending delivery of the LED UV press.

Food safety

The LED UV ink series is designed with a raw material selection to maintain the food safety and migration characteristics as obtained with other RESUCAT® 210 ink series.

This has already been confirmed by a 3rd party institute for a customer who has fully approved the system and has printed full scale since April 2023.

Environmental advantages

An environmental benefit of using UV LED lamps is that the technology supports phasing out of the traditional UV mercury lamps and thereby contributes in the transition to a mercury-free and sustainable environment.

For the work environment, UV LED also contributes to eliminating the emission of ozone, which is known from traditional lamps and comes with the unpleasant “chemical smell.”

Your needs?

The RESUCAT® ink range is also suitable for flexible packaging, including shrink sleeves, shrink bags, retort & wet sterilization resistant print and much more.

We are happy to assist in your process around UV LEDs and how it can be implemented by your business.

About Resino

Resino Inks is a valued partner in high- quality ink systems specializing in food printing inks and exports inks and varnishes to 5 continents and over 64 countries.

We are experts in developing tailored, innovative solutions in close cooperation with our customers and we meet strict regulatory requirements and high demands for product performance and quality.

Our most noble task is to make life as easy and safe as possible for our customers and end users.

We have strong position within printing inks for direct food contact and we constantly consider ways of integrating sustainability in our product development both in the form of renewable resources and biodegradability. We also enjoy a global leading position in printing ink for sausage casings and non-Woven hygiene materials, including UV curing products for flexo/gravure and in the process of developing inkjet inks for these markets.

We at Resino welcome your challenges. Please contact us for a personal dialogue.